How to choose the right hat blanks

2024-04-07

Where to buy machine embroidery supplies?

2024-04-17BEGINNER TUTORIALS

About the choice and use of lubricating oil for embroidery machines.

POSTED ON APRIL 17th,2024 BY BAi

As is well known, lubricating oil plays a crucial role in the maintenance of embroidery machines. Correctly choosing and using lubricating oil helps ensure the normal operation of the embroidery machine. This article will delve into how to choose the right lubricating oil and the correct methods for use and maintenance.

The choice of lubricant for embroidery machines

Grease and sewing machine oil are the only two lubricants used in embroidery machines. When choosing lubricants for your embroidery machine, please remember to carefully read your machine manual and use the lubricant recommended by the manufacturer. Do not use inferior lubricants, as they may damage the machine.

Sewing machine oil:

It is commonly used to lubricate moving parts of embroidery machines, such as shafts and bearings. Ordinary white sewing machine oil is recommended, as it has the characteristics of low viscosity, easy volatility, and good wear resistance. You can find it in almost any craft supply store.

Lubricating grease:

Apply lubricating grease to cam and other positions to ensure the normal operation of the motor. It is recommended to use oil with medium viscosity, high temperature resistance, oxidation resistance, and non-volatile characteristics, such as Tri-Flow Clear Synthetic Grease, Lucas White Lithium Grease, etc.

There is a wide variety of brands for embroidery machine lubricating grease, each with its own characteristics and suitable scenarios. Here are some common brands of embroidery machine lubricating grease and their characteristics:

-Tri-Flow Clear Synthetic Grease:

High Performance: Formulated for high-performance lubrication, this grease ensures the smooth operation of mechanical components in various applications.

Transparent Formula: Unlike opaque or colored traditional greases, Tri-Flow Clear Synthetic Grease features a transparent formula. This feature allows easy inspection of lubricated parts, making it ideal for applications where aesthetics or cleanliness is crucial.

Versatility: Suitable for a wide range of applications, including automotive, industrial, marine, and household uses. Whether used for bearings, gears, cables, or other mechanical components, this grease provides reliable lubrication.

Water and Contaminant Resistance: The formula of Tri-Flow Clear Synthetic Grease resists water washout and prevents contaminants such as dust, dirt, and debris. This ensures long-lasting lubrication and helps prevent premature wear of components.

Wide Temperature Range: Performs well across a wide temperature range, suitable for both low and high-temperature applications. Whether in cold environments or hot conditions, this grease maintains its lubricating performance.

Compatibility: Tri-Flow Clear Synthetic Grease is compatible with a variety of materials commonly found in mechanical systems, including plastics, rubber, and metals. This compatibility ensures it can be safely used with different components without causing damage or performance degradation.

-Lucas White Lithium Grease:

Excellent Lubrication: This grease provides excellent lubrication for a wide range of applications, including automotive, industrial, marine, and household uses. It effectively reduces friction and wear on moving parts, ensuring smooth operation and extending the service life of equipment and components.

Water and Heat Resistance: The formula of Lucas White Lithium Grease resists water washout, maintaining its lubricating performance even in wet conditions. It also has good heat stability, remaining effective at high temperatures without melting or running off.

Long-lasting Protection: The grease forms a durable protective barrier between metal surfaces, preventing corrosion, rust, and oxidation. This long-lasting protection helps prevent premature component failure and ensures reliable performance in harsh environments.

Versatility: It is suitable for a variety of automotive and industrial components, including bearings, chassis parts, hinges, slides, and gears. Whether applied to heavy-duty equipment or everyday household items, Lucas White Lithium Grease provides reliable lubrication.

Easy Application: Due to its smooth consistency and adherence to surfaces, this grease is easy to apply. It can be conveniently dispensed from tubes or aerosol cans, allowing precise application to specific areas.

Compatibility: Lucas White Lithium Grease is compatible with a variety of materials commonly found in mechanical systems, including metals, plastics, and rubber. This compatibility ensures it can be safely used with different components without causing damage or performance degradation.

-Super Lube Synthetic Multi-Purpose Grease:

Versatility: This synthetic lubricating grease is designed for multi-purpose use, suitable for a wide range of applications across various industries. It can be used in automotive, marine, industrial, and household environments, providing lubrication for different components and equipment.

High Performance: The formula of Super Lube Synthetic Multi-Purpose Grease delivers high performance even under demanding conditions. It effectively reduces friction and wear on moving parts, ensuring smooth operation and extending the service life of equipment.

Wide Temperature Range: It exhibits excellent thermal stability, allowing it to operate effectively across a wide temperature range from extreme cold to high heat. This ensures consistent lubrication and protection in different operating environments.

Water Resistance: This grease possesses strong water resistance, preventing washout even in wet conditions and maintaining its lubricating properties. This helps prevent corrosion and rust on metal surfaces, enhancing the durability of components.

Chemical Compatibility: Super Lube Synthetic Multi-Purpose Grease is compatible with a variety of materials commonly found in mechanical systems, including metals, plastics, and elastomers. It can be safely used with different components without causing damage or degradation.

Long-lasting Protection: It forms a durable protective film on surfaces, providing long-lasting lubrication and preventing friction, wear, corrosion, and oxidation. This helps extend maintenance intervals and reduce the frequency of reapplication.

Clean Application: The formula of this grease is clean, non-toxic, safe, and easy to handle. It is free from harmful additives or contaminants, ensuring cleaner application and reducing the risk of environmental pollution.

The above are some common brands of embroidery machine lubricants, each with its unique characteristics and advantages. You can choose the product that suits your needs and machine requirements.

Usage of Embroidery Machine Lubricant

In addition to knowing how to choose the lubricant, we also need to understand how to use it correctly.

Before explaining the lubrication steps, let's first understand some tools needed for machine maintenance.

Cloth: Similar to the microfiber cloths used for computers. Ultra-fine fiber cloths are very useful because they are washable and reusable.

Oil brush or cotton swab: The oil brush has short bristles, and you can prepare multiple brushes to ensure they are clean when used.

Soft brush: This helps to remove lint and other debris. If you're unsure what soft brush to buy, a computer keyboard brush works well!

Oil pen: Usually included with commercial machines and some household machines. Most oil pens have a twist-off tip where sewing machine oil can be poured in. Remember not to fill it too full to prevent spillage.

Small oil can: In addition to the oil pen, you can also prepare a small oil can. The capacity of the small oil can is larger than that of the oil pen, but the oil pen is more portable.

Screwdriver: Prepare a screwdriver to remove specific areas of protective covers, making it easier to lubricate the machine internally.

Below are the usual steps for oiling the machine:

#1 Power off and unplug: For safety purposes, disconnect the embroidery machine from power before any lubrication operation and ensure the machine is not running.

#2 Remove the needle, needle plate (if indicated), and anything obstructing access to the oil points.

#3 Use a soft brush to gently remove any visible lint and debris.

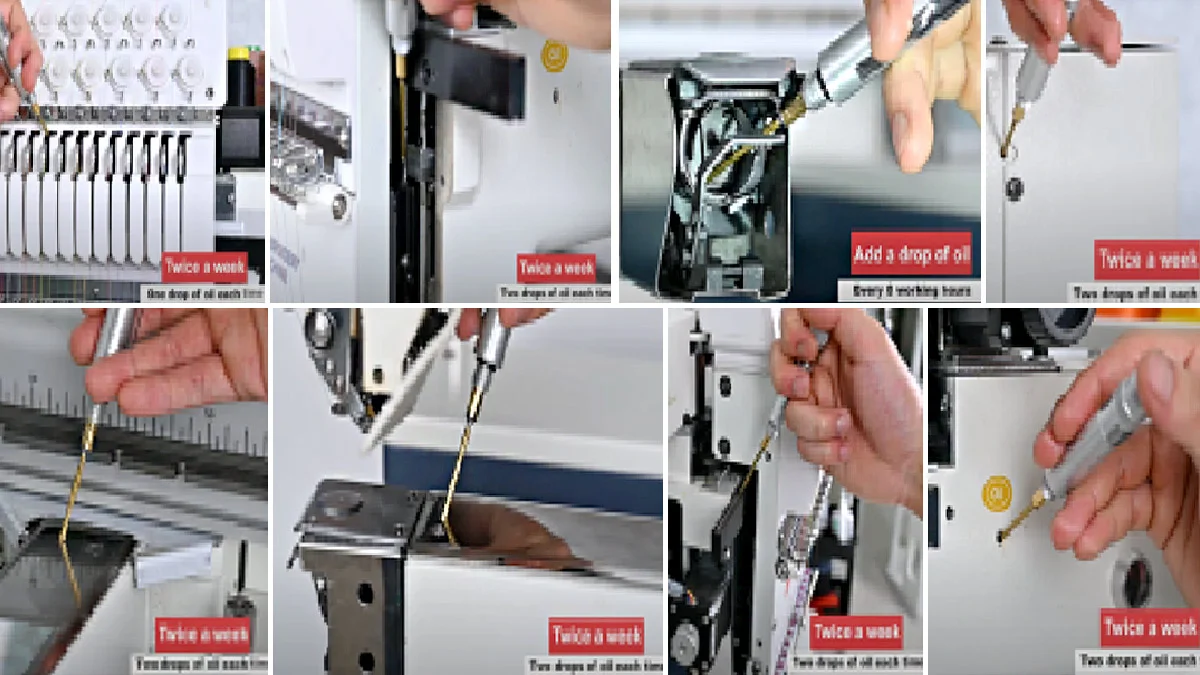

#4 Oil application: Locate the lubrication points and apply oil using a dropper tool. The parts that need lubrication are typically the moving parts of the machine, including the oil hole on the machine head (two drops each time), the oil hole on the shuttle bed surface (two drops each time), the guide rails (for this step, you need to move the machine body and evenly apply oil on both sides of the guide rails, two drops each time), bobbin hook (note: remove the bobbin case, one drop each time), the drive rod (two drops each time), and all needle bars (one drop each time).

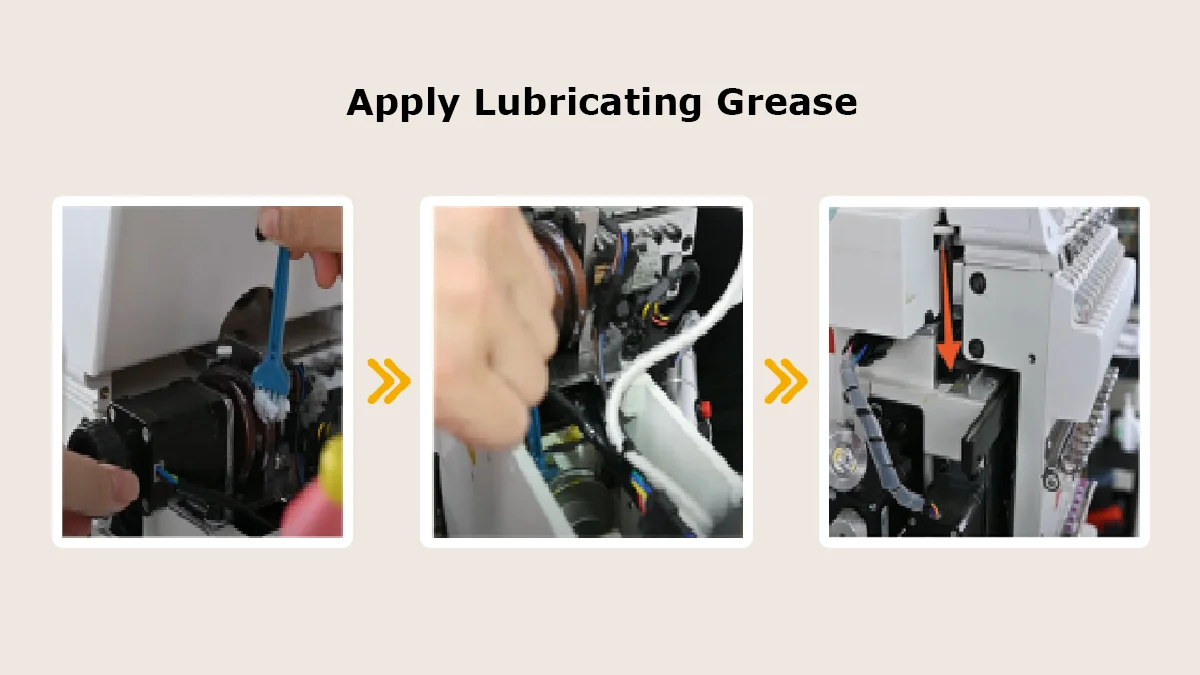

#5 Grease application: Take out a brush, dip it into an appropriate amount of grease, and evenly apply it. Ensure your brush is clean. Typically, there are three places that need grease application:

-The cam inside the motor protection cover. You need to remove the outer cover first.

-The cam inside the main spindle. Similarly, you need to remove the protection cover first.

-The rear part behind the guide rail. Adjust the needle position to move the machine head to the far right, then you can see the rear part behind the guide rail.

It's important to turn the corresponding knobs while applying grease to these areas.

After lubrication, excess oil may seep out. If not cleaned in time, it may soil the machine surface or even drip onto the embroidery fabric. Therefore, you need to use a cleaning cloth or cotton swab to clean it up.

Correct selection and use of lubricants are crucial for the efficiency and lifespan of the embroidery machine. Through this article's introduction and guide, we hope readers can better understand how to choose the appropriate lubricant, and master the correct usage and maintenance methods to ensure the stability and reliability of the embroidery machine.

-1.png)