How to Speed Up Embroidery Production - Tips for Increasing Efficiency

2025-04-29

Exploring Embroidery Machine Speed Issues: A Practical Guide

2025-05-30EMBROIDERY TIPS

Common Mistakes Made by Beginners in Embroidery

POSTED ON MAY 9th, 2025 BY BAi

Embroidery machines are not something you come across every day, so it's inevitable for beginners to make many mistakes when they first start using them. This is completely normal. This article will explain some common mistakes beginners make when embroidering and provide some corresponding solutions. Hopefully, this will be helpful to you.

1.Forgetting to use stabilizer

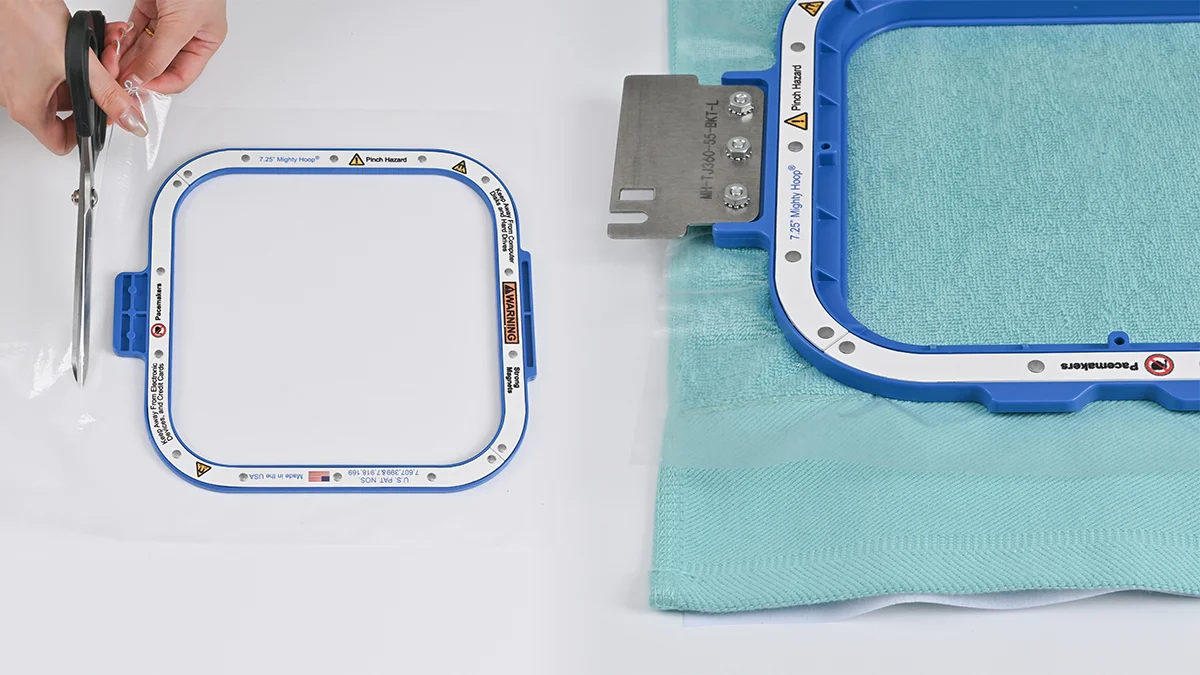

Forgetting to place the stabilizer underneath the fabric when securing it in the embroidery hoop.

No matter what type of garment you are embroidering, stabilizer is a very important auxiliary material when using an embroidery machine, as it greatly affects the quality of the embroidery. The fabrics we commonly use in embroidery are often very soft, and the needle can cause some pulling and distortion of the fabric. The stabilizer helps to provide additional support, preventing the fabric from distorting or developing holes, ensuring that the final embroidery is smooth and wrinkle-free.

To avoid forgetting to use stabilizer, we can keep the stabilizer together with the embroidery fabric. When it's time to embroider, pick up both together as a reminder to not forget to use the stabilizer.

2.Hooping too tightly or too loosely

After securing the embroidery, if the fabric is hooped too loosely, it can lead to loose tension, which may cause thread nests underneath or increase the risk of skipped stitches. On the other hand, if the fabric is hooped too tightly, it will increase the tension on the fabric and thread, raising the risk of thread breakage. Additionally, the embroidery machine may pull the fabric, causing distortion and compromising the appearance of the embroidery.

So before you completely secure the fabric, you need to carefully check if the hooped fabric is smooth and taut without any wrinkles. If it's not smooth, you can gently tug the fabric around the edges of the embroidery hoop to make it flat. Be careful not to pull too hard, as this can make the fabric too tight.

3.Not adjusting the embroidery thread tension properly

Thread tension also greatly affects the quality of the embroidery, including both the top thread tension and the bobbin thread tension.

When the tension is not set correctly, it often leads to issues such as thread breakage, thread jams, thread nests, or bobbin thread showing through. Different types of embroidery thread require different tensions, and different types of embroidery projects also need varying tensions.

Before starting your work, you can use a tension gauge or the H-test method to check if the tension is appropriate. By following these tension testing steps, you can avoid many problems later on, improve the quality of your embroidery, and increase work efficiency.

4.Using the wrong embroidery needle

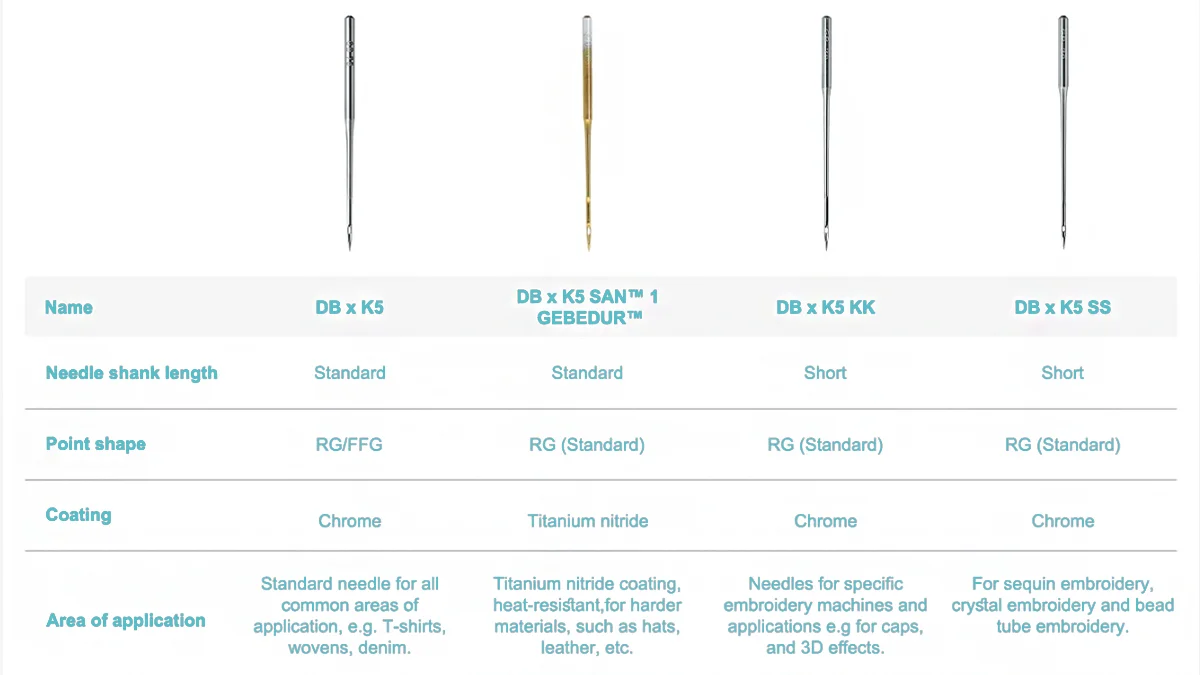

Embroidery needles are essential materials for embroidery machine work. There are many types of embroidery needles available on the market, each with different functions. Using the wrong type of embroidery needle can significantly affect the smoothness of the embroidery process and the quality of the finished embroidery, while also increasing needle wear.

Learn and understand the functions of different types of embroidery needles, paying special attention to the differences between needles used for flat embroidery and those used for cap embroidery. Use the appropriate needle for each situation to maximize its effectiveness. Additionally, you can experiment with different needles to find the one best suited for each project.

5.Incorrect threading of the embroidery thread

Embroidery threads have specific threading steps and positions on the embroidery machine. Errors in the order or placement of threading can cause the thread to malfunction during operation. If you encounter issues like thread breakage or loose threads, it's recommended to first check whether the threading is correct.

Make sure to thread the machine exactly as shown in the operation manual to avoid any issues caused by incorrect threading. Also, be mindful during the embroidery process to check if the thread gets caught or if there are areas where the thread should make one and a half turns but comes loose.

6.Not following the prescribed procedure

From preparation to the completion of the embroidery, there are many steps involved, such as securing the fabric, adjusting the arm based on the hoop, attaching the hoop to the machine, selecting the design, and choosing the colors. Missing any of these steps can result in an imperfect final product or even embroidery failure.

Operate the embroidery machine according to the correct procedure, especially when using the control screen. Follow the prompts in sequence to complete each step, and you will be able to produce satisfactory embroidery. If you notice any issues, you can press the emergency stop button to force the machine to shut down, then restart it and identify the problem before trying again.

7.Not taking time to check everything before starting the embroidery

If you're eager to see the final product and skip checking everything before starting, you might end up with unnecessary issues.

Before starting, you can check the following:

- Ensure that the fabric is properly hooped and the orientation of the hoop is correct. Avoid having the design upside down or rotated.

- Verify that you have enough thread (both bobbin thread and top thread) to complete the design.

- Confirm that you have all the thread colors needed for the pattern.

- Check that the embroidery hoop is correctly attached to the machine.

- Make sure there is enough clearance for the hoop to move without hitting the frame.

- Verify that the needle used is appropriate for the fabric being embroidered.

- Ensure that the needle is centered on the marked center position of the fabric.

Develop the habit of carefully checking this checklist before pressing the start button. It can help you avoid some disappointing outcomes.

8.Leaving the embroidery machine to work on its own

Leaving the embroidery machine to work on something else while it is running is not advisable.

Even if you have followed the setup procedures correctly, you should not leave the machine unattended for too long. There could be potential issues, such as thread breakage or skipped stitches, that may arise unexpectedly. It is recommended to stay close to the embroidery machine so you can take immediate action if any problems occur and stop the machine if necessary.

9.Not testing the embroidery design

When you get a new embroidery design, you might be tempted to use it directly on your product. However, if the result is not satisfactory and you haven't tested it first, you may end up with a product that cannot be modified, leading to having to abandon it.

After obtaining a new embroidery design, it's recommended to first test it on scrap fabric. If the results are satisfactory, you can then apply it to the product fabric. This way, if the final result is not as expected or if there are issues, you can make adjustments based on the initial test, thus reducing the cost of trial and error.

10.Not performing regular maintenance on the embroidery machine

Embroidery machines also require regular care and maintenance. The more you take care of it, the more you will benefit from it. You can perform the following maintenance tasks regularly:

- Clean the thread spool stand to prevent dust buildup from hindering operation.

- Turn off the power and cover the machine with a dust cover when not in use.

- Lubricate the embroidery machine once a week, and lubricate the rotary hook more frequently, ideally every 5-6 hours of operation.

This article basically covers some of the common mistakes that newbies make when embroidering, and hopefully it will help you to avoid some of these mistakes and try to carry out each and every embroidery project as perfectly as possible. As a novice, mistakes are inevitable when using an embroidery machine, but don't worry, just take your time and gain experience, you can also master it, and with more practice and experience, you will also be able to master the skills of operating an embroidery machine and produce beautiful and touching embroidery works!

-1.png)