Profitable T-shirt embroidery business

2024-10-25

Chatting about embroidery machine bobbins

2024-11-06EMBROIDERY TIPS

Embroidery Machine Needle Skipping Troubleshooting and Solutions

POSTED ON NOVEMBER 1st,2024 BY BAi

During the embroidery process, embroiderers sometimes encounter a common issue known as needle skipping. This situation can be frustrating and diagnosing it can be even more annoying. But fret not! In this article, we will explore the reasons cause needle skipping and provide you with effective solutions to solve this problem. If you've ever wondered how to resolve the issue of needle skipping on an embroidery machine, then keep reading!

In this article, the following aspects will be discussed:

#1 What is needle skipping?

#2 Causes of needle skipping

#3 How to resolve the issue of needle skipping

#1 What is needle skipping?

In some cases, "needle skipping" and "dropped stitches" may be used interchangeably or confused with each other, but strictly speaking, they are different situations:

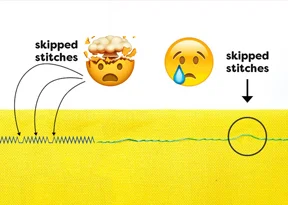

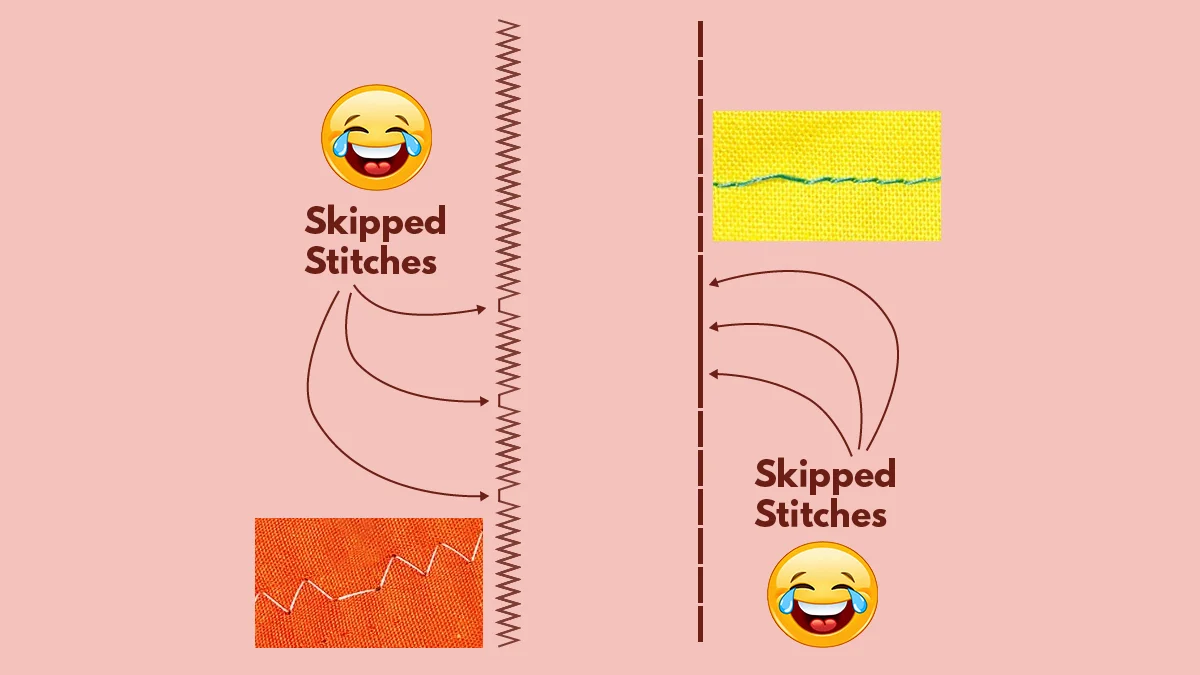

- Skipped Stitch usually refers to an embroidery machine that is working with certain stitches that do not fully penetrate the fabric or backing, or the threads are not pulled up. This can result in some lines or details in the embroidery pattern being missing and appearing hollow.

- Dropped Stitch on the other hand, means that during the embroidery or sewing process, the needle of the machine does not pass through the fabric or backing, but skips directly to the corresponding position, resulting in a missed stitch action.

While both situations involve the needle not properly penetrating the fabric or backing during operation, they are technically distinct issues.

#2 Causes of needle skipping

-1 Needle type or size is incorrect

- Needle size too large: Choosing a needle that is too large can cause excessive pressure from the needle tip on the fabric, which may prevent it from smoothly penetrating the fabric and cause it to skip or damage the fabric surface.

- Needle size too small: Choosing a needle that is too small may result in the needle not being properly secured within the fabric, making it prone to bending or deviating from the intended path during penetration, causing the needle to skip out of the fabric.

- Improper needle tip design: Incorrect needle tip shape or design can hinder the smooth penetration of the embroidery needle into the fabric. For example, a blunt or dull needle tip may get stuck between fabric fibers instead of smoothly piercing through, leading to needle skipping.

- Incompatible fabric type: The needle type and size should match the fabric being used. Different fabrics have varying thicknesses, textures, and densities. Choosing an inappropriate needle may fail to effectively penetrate the fabric, resulting in needle skipping or slipping.

-2 Incorrect thread tension

- Excessive thread tension: If the thread tension is too high, it can cause the fabric fibers to be pulled tightly when the embroidery needle passes through. This tension can create resistance during the penetration process, causing the needle to skip or disengage from the fabric.

- Insufficient thread tension: Insufficient thread tension can result in loose thread that is not securely held in place on the fabric. During embroidery, the needle may fail to grip the thread firmly, leading to needle slippage or skipping out of the fabric.

- Inconsistent thread tension: Thread tension should be consistent throughout the embroidery process. If the thread tension is unstable or inconsistent, the embroidery needle will encounter irregular resistance during penetration. This irregular resistance can cause the needle to skip or deviate from the intended path.

-3 Incorrect gap of rotary hook

- The gap of rotary hook is too large: The rotary hook is a component located at the bottom of the embroidery machine and is responsible for forming the loop of the embroidery thread. The gap of rotary hook is too large, the embroidery needle may enter the gap instead of smoothly penetrating the fabric. This can cause the needle to skip or disengage, affecting the accuracy of the embroidery.

- Insufficient gap of rotary hook: Conversely, if the rotary hook gap is too small, the embroidery needle may encounter resistance during penetration, preventing it from smoothly passing through the fabric. This can result in needle skipping or thread breakage.

- Uneven gap of rotary hook: If the gap of rotary hook is uneven during the embroidery process, with some areas having larger gap while others have smaller gap, the embroidery needle will encounter irregular resistance during penetration. This irregular resistance can cause the needle to skip or deviate from the intended path.

- Rotary hook wear or damage: Prolonged use or improper maintenance can lead to wear or damage to the rotary hook, causing issues for the embroidery needle during penetration and increasing the risk of needle skipping.

#3 How to resolve needle skipping issues

-1 Check the embroidery needle type and size

The first step in troubleshooting needle skipping issues is to ensure that the embroidery needle type and size being used are suitable for the fabric. The selection of the embroidery needle directly affects the piercing effectiveness and stability of the embroidery. Here are the reasons why this step is crucial:

- Needle tip shape and type: Different types of embroidery needles have different needle tip shapes and types. These characteristics directly impact the needle's piercing ability and stability on the fabric.

- Needle size and fabric thickness: The embroidery needle size should match the thickness of the fabric being used. If the embroidery needle is too thin, it may not penetrate thicker fabrics effectively, leading to needle skipping or thread breakage. Conversely, if the embroidery needle is too thick, it may cause excessive damage on finer or delicate fabrics.

- Fabric type and fiber properties: Different fabric types have distinct fiber properties and structures, such as cotton, silk, linen, etc. Each fabric has its unique requirements and characteristics. Choosing an embroidery needle suitable for a specific fabric type ensures proper interaction between the needle and fibers, reducing the risks of needle skipping and fabric damage.

-2 Adjust the thread tension

Regular Hat Embroidery: Traditional embroidery materials such as regular embroidery threads and backing materials are used to complete flat embroidery designs:

- Check the tension device of the embroidery machine: Embroidery machines are typically equipped with tension adjustment knobs for adjusting thread tension. These adjustment devices are usually located on the top of the embroidery machine or near the thread spool. Gradually adjust the tension device as needed, observing the changes in thread tension until the desired tension level is achieved.

- Test the embroidery results: Before proceeding with actual embroidery, it is recommended to perform test embroidery to check if the thread tension is appropriate. Select a fabric sample similar to the actual embroidery and observe the movement of the embroidery needle and the tension of the thread. If there are issues such as needle skipping or thread breakage, it may be necessary to adjust the thread tension.

- Gradually adjust the tension: Both loose and tight thread tension can contribute to needle skipping issues. If the thread tension is too loose, gradually increase the tension until it reaches an appropriate level. If the thread tension is too tight, gradually decrease the tension until it reaches an appropriate level. Making gradual adjustments allows for more precise tuning of thread tension to achieve the best results.

-3 Adjusting the gap of rotary hook

Adjusting gap of rotary hook is another crucial step that can help prevent needle skipping issues. The gap of rotary hook refers to the vertical distance between the rotary hook and the needle eye, and adjusting the correct gap ensures smooth passage of the needle and thread through the fabric without causing needle skipping or thread breakage. Here are some suggestions for adjusting the gap of rotary hook to prevent needle skipping:

- Refer to the embroidery machine manual: Different embroidery machines may have different methods and steps for adjusting the gap of rotary hook. It is best to consult the user manual of the embroidery machine you are using to learn the specific adjustment methods and operating guidelines. The manual usually provides detailed instructions and steps for adjusting the gap of rotary hook.

- Determine the correct range of gap of rotary hook: It is important to understand the correct range of gap before adjusting the gap . This information can usually be found in the embroidery machine manual or related resources. Different fabrics and threads may require different gap , so make sure you are aware of the appropriate range for the fabric and thread you are using.

- Adjust the gap of rotary hook adjustment device: Embroidery machines are typically equipped with adjustment devices that control the gap between the rotary hook and the needle eye. These adjustment devices are usually located beneath or on the side of the embroidery machine. By adjusting the device, you can increase or decrease the distance between the rotary hook and the needle eye.

- Perform test embroidery: After adjusting the gap of rotary hook, perform test embroidery to evaluate the effectiveness of the adjustment. Select a fabric sample similar to the actual embroidery and observe the needle's piercing and the stability of the thread. If needle skipping issues persist, it may require fine-tuning of the gap of rotary hook.

- Gradual fine-tuning: If needle skipping or thread breakage issues are encountered, you can resolve them by gradually fine-tuning the gap of rotary hook. Fine-tuning should involve small adjustments to ensure smooth passage of the needle and thread through the fabric, maintaining a stable embroidery process.

When using an embroidery machine, needle skipping can be a frustrating issue. However, by understanding the causes and implementing the solutions provided in this guide, you can effectively resolve this problem. Remember to use the correct needle type and size, replace dull or damaged needles, adjust thread tension, and so on. With these steps, you no longer have to worry about needle skipping affecting your perfect embroidery designs.

-1.png)