Where to get embroidery supplies?

2025-01-27

Pattern 950064

2025-02-14EMBROIDERY TIPS

How to improve the quality of hat embroidery

POSTED ON FEBRUARY 8th,2025 BY BAi

In recent years, embroidered hats have become popular fashion accessories. They not only provide sun protection but also allow individuals to express their personal style, making them highly favored by customers. However, not all embroidered hats are created equal. Some may have lower embroidery quality, which can affect their overall appeal and customer satisfaction. In this article, we will explore various techniques and tips to improve the quality of hat embroidery. Whether you are an embroidery enthusiast or a store owner looking to enhance hat embroidery, this guide will provide you with practical advice.

#1 Choose High-Quality Hat Blanks

-1 Embroidery Thread

The first step in improving the quality of embroidered hats is to select high-quality hat blanks. You can embroider on various hat materials, including cotton, polyester, wool, and blends. However, when embroidering, it is essential to consider the fabric texture and thickness. It is recommended to use hat blanks made from durable materials such as cotton or polyester blends. These materials not only provide a sturdy embroidery area but also ensure the longevity of the hat.

- Cotton Hats: Cotton hats are an ideal choice for hat embroidery. Cotton fabric is soft, comfortable, easy to embroider, and can withstand the tension of the embroidery process. Additionally, cotton hats usually have good breath ability and sweat absorption, making them ideal for hot weather.

- Polyester Blend Hats: Polyester blend fabrics are another commonly used hat material. They offer high stability, wrinkle resistance, and can withstand stretching and tearing during the embroidery process. Polyester blend fabrics also have excellent color fastness, ensuring the longevity of vibrant colors.Using hat blanks made from fragile or low-quality materials to cut costs may not provide sufficient support for intricate embroidery designs. Additionally, consider the style and fit of the hat to ensure it complements your desired design.

#2 Use High-Quality Thread and Needles

-1 Embroidery Supply Stores

The choice of thread and needles can significantly impact the quality of embroidery.

Select strong and colorfast threads to ensure durability and prevent fading. Inferior threads can result in abrasion, breakage, and inconsistent stitching. Polyester threads are generally considered the best choice for hat embroidery. They offer durability, colorfastness, and resistance to fading, making them suitable for long-term use. Additionally, choose the appropriate needle size and type based on the hat's fabric to ensure smooth stitching without causing any damage to the material.

Choose high-quality embroidery needles with durable, sharp characteristics. Different types of embroidery needles should be selected for hats made of different materials. For example, soft beanies should use round-point needles (BP). The round tip prevents the yarn in the fabric from fraying. It pushes the yarn away instead of piercing it, which may form holes. For hard structural hats, regular needles or pointed needles should be used. Of course, if you choose a stronger titanium needle (PD), it will be better because it can reduce needle breakage, bending and deformation.

Common hat embroidery needles are 75/11 size, which is the most popular general size, while the thicker and harder 80/12 is more suitable for embroidering structural hats and 3D cap embroidery.

#3 Pay Attention to Design Placement

The placement of the embroidered design plays a crucial role in the overall quality of the hat. When deciding the position of the design, consider the size and shape of the hat. Avoid placing it too close to the edges or seams, as this can lead to distortion or uneven stitching. Ensure that the design is proportionate and aligned with the hat's dimensions and contours for the best visual impact. Also, consider the wearer's comfort and visibility when determining the ideal placement of the design.

#4 Maintain Proper Tension

Tension plays a crucial role in achieving precise embroidery. Improper tension can result in loose or wrinkled embroidery threads, affecting the overall quality of the design. Regularly check and adjust the tension of your embroidery machine to ensure consistent and even stitching. Typically, the tension for embroidering hats should be slightly higher than embroidering garments. This is because hats are often made of thicker fabrics, and the embroidery area is relatively smaller, requiring more tension to keep the embroidery thread stable during the process. The tension for hat embroidery may vary depending on the specific circumstances, but here are some common tension ranges (measured in gf, grams of force):

- Soft Hats (such as cotton hats): For softer hat materials, the tension range is typically between 150 and 250 gf.

- Structured Hats (such as hats with a stiff brim): For structured hats, which have stiffer materials, higher tension is needed to ensure embroidery stability and clarity. The recommended tension range is usually between 250 and 350 gf.Remember to adjust the tension gradually and test the stitching on scrap fabric or a sample piece before embroidering on the actual hat to achieve the desired results.

#5 Use Appropriate Stabilizer

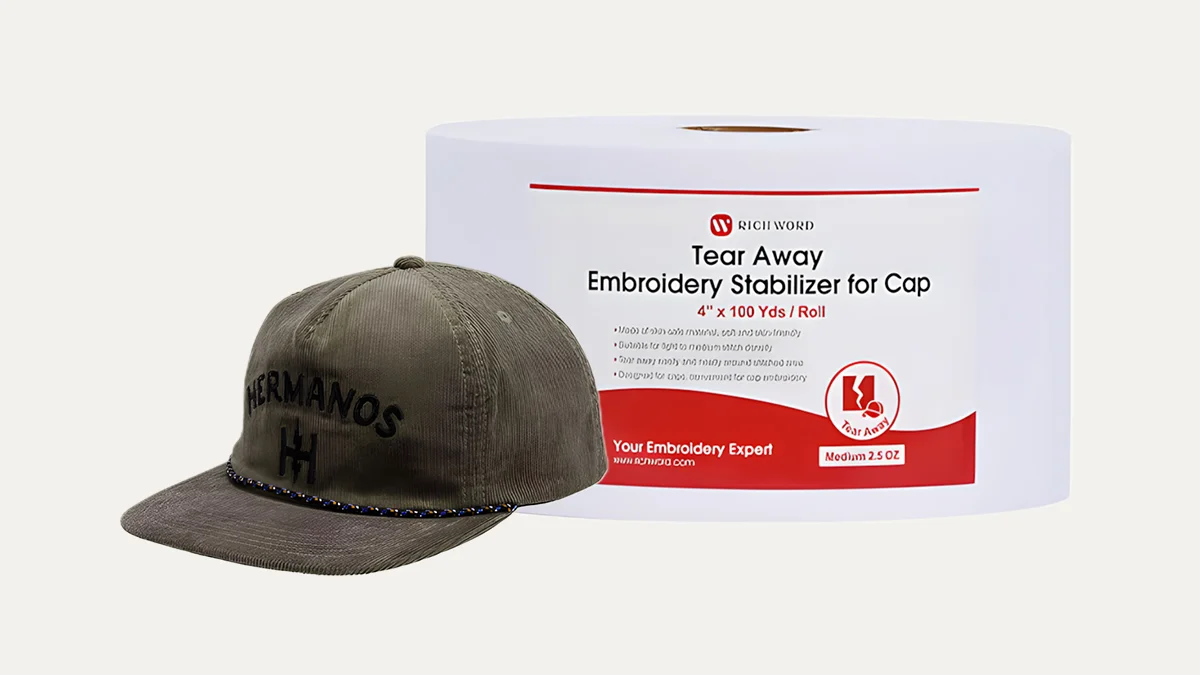

For certain hat fabrics, using embroidery stabilizer can provide additional support and stability, preventing the embroidery thread from sinking into the fabric during the stitching process. Choose embroidery stabilizer that is suitable for the hat material and embroidery design, and properly install it beneath the embroidery area. Two commonly used types of stabilizers for hat embroidery are Tearaway stabilizer and Cutaway stabilizer.

- Tearaway Stabilizer: Tearaway stabilizer is one of the common choices. It is typically made of paper or fiber materials and offers a certain level of strength and stability. Tearaway stabilizer is suitable for lightweight hat fabrics such as cotton hats. After embroidery is complete, the stabilizer can be torn away from the embroidery area. Tearaway stabilizer is suitable for simple embroidery designs and lighter-weight hat materials.

- Cutaway Stabilizer: Cutaway stabilizer is a more stable and durable option. It is usually made of polyester or cotton fibers, providing stronger support. Cutaway stabilizer is suitable for complex or large embroidery designs and hats that require long-term stability. After embroidery is complete, the Cutaway stabilizer needs to be left in place on the embroidery area to provide long-lasting support and stability.

#6 Ironing the Hat

After completing the embroidery, you can consider using an iron to gently press the hat. This can help make the embroidery flatter and ensure a tight bond between the embroidery thread and the hat fabric. Before ironing, make sure that both the hat and the embroidery thread can withstand the ironing temperature. Here are two common materials used during ironing:

- Heat-Sensitive Film: Heat-sensitive film is a transparent adhesive film that can be used to cover the embroidery area. Cut the heat-sensitive film into the same size and shape as the embroidery area, then place it on top of the embroidery. Use a hot iron to briefly press the heat-sensitive film and the embroidery area together. This provides additional stability and protection, preventing the embroidery thread from loosening or coming off.

- Thin Fabric or Tissue: Using a hot iron is another common post-processing method. Set the iron to the appropriate temperature (according to the requirements of the embroidery thread and the hat fabric), then gently press the embroidery area. Before ironing, make sure to place a thin fabric or tissue on top of the embroidery to prevent direct contact between the iron and the embroidery thread. Ironing can make the embroidery flatter and help the embroidery thread bond better with the hat fabric.

#7 Perform Quality Control Inspection

To ensure the highest quality of embroidered hats, a thorough quality control inspection must be conducted. Inspect each hat individually for any defects such as loose threads, uneven stitching, or design misplacement. Address any issues and make necessary adjustments before delivering the order to the customer.

Additionally, to maintain the quality of embroidered hats, it is recommended to hand wash them using a mild detergent and cold water. Avoid using harsh chemicals or bleach as they can damage the embroidery. After washing, reshape the hat gently and allow it to air dry to prevent deformation. Avoid prolonged exposure to sunlight.

That concludes the content of this blog post. I hope it was helpful to you. If you have any other methods to improve the quality of embroidered hats, feel free to share them with us in the comments section. Thank you!

-1.png)