Two Single Head Machines vs One Double Head Machine

2024-03-18

How to maintain embroidery machine

2024-04-03BUSINESS TIPS

Take an in-depth analysis: VISION V22-2 - dual head commercial industrial embroidery machine

POSTED ON JANUARY 10th,2024 BY BAi

As soon as the new model VISION V22-2 hit the shelves, many of BAi's regular customers came to ask about this machine and wanted to know more about it. Today we are dedicated to introduce V22-2 to you and bring you an in-depth understanding of this new model.

# What are the upgrades to VISION V22-2

# Why you need VISION V22-2

I would like to briefly introduce BAi's VISION V22-2 to you. The V22-2 embroidery machine is a dual head commercial embroidery machine with an integrated casting molding technology for a beautiful appearance and a sturdy and stable structure. The machine system is equipped with self-developed INSTITCH I5 operating system, which brings you the ultimate experience in operation.V22-2 is equipped with 15 needles and standard accessories for each embroidery head, which is very suitable for developing the embroidery business, embroidering hats, clothes, bags, hoodies, leathers, shoes, patches and so on.

# What are the special upgrade points of VISION V22-2?

1. Electronic control

The electric control of VISION V22-2 is equipped with the in-house developed INSTITCH I5, which is to a large extent more convenient for novices to use, easy to operate, and easier to embroider hats.

Why is it so easy to operate, even for novices: Because the INSTITCH I5 simplifies the previously complex operating procedure, the electronic control is equipped with a step-by-step guide, so that even if you are new to embroidery, you will be able to familiarize yourself with the machine in a short time.

In addition to making the system easier to operate, the INSTITCH I5 also makes it easier to embroider hats, as the INSTITCH I5 is configured with different angled frames, allowing it to be flexibly adapted to embroider hats made of a variety of materials, and to meet the needs of customers who would like to embroider on the front or back of their hats, thus realizing the versatility of the embroiderer's embroidery.

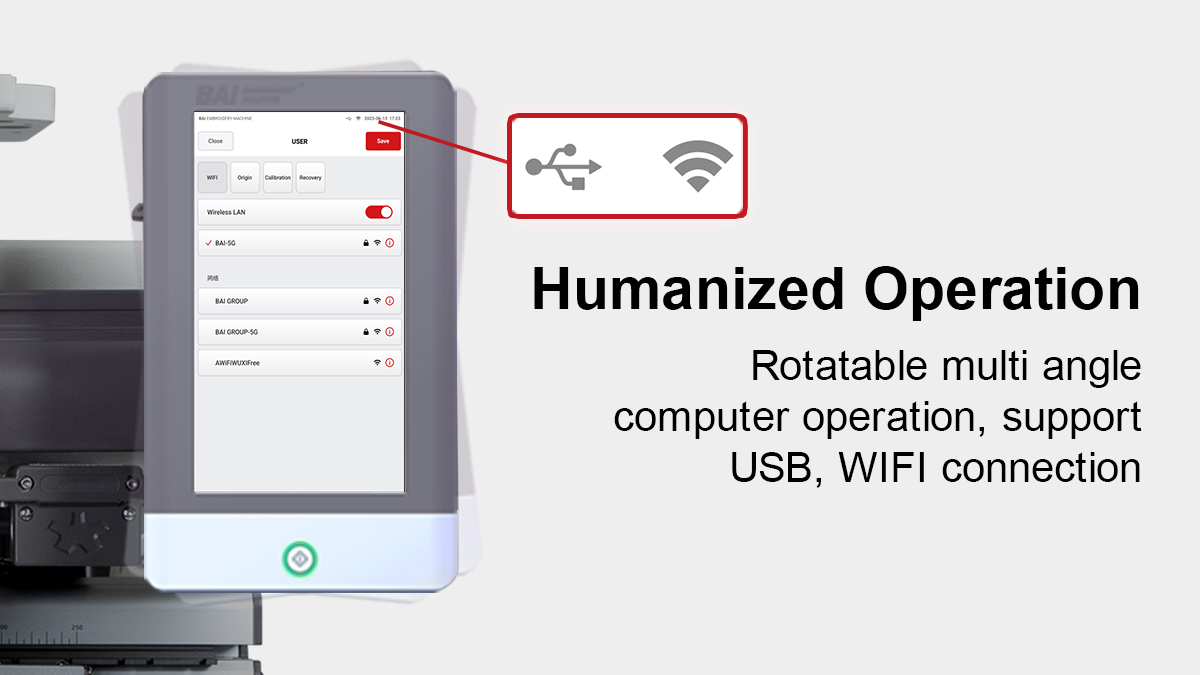

When it comes to embroidery patterns, INSTITCH I5 is also faster in processing embroidery patterns.INSTITCH I5 supports USB and WIFI connection, you can choose the suitable way to import embroidery patterns, meanwhile, it also supports you to import, export or delete embroidery patterns in batch. This electronic control supports the free combination and division of embroidery patterns, which satisfies you to handle embroidery patterns flexibly and individually. You don't need to use patching software, just combine or divide the existing embroidery patterns on the electronic control, you can flexibly create more rich embroidery designs. For those who need to mass produce patches, INSTITCH I5 is definitely something you can't afford to miss. You only need to perform one operation on INSTITCH I5 to get multiple patches, which improves the efficiency of embroidery and also allows you to complete batch embroidery work easily.

2. Wheel spring double inspection system

Thread breakage has always been a problem for embroiderers during the embroidery process, so we upgraded the machine to a wheel-spring dual detection system.Instead of using the regular thread breakage wheel detection system, the VISION V22-2 has been upgraded to a wheel-spring dual detection system. This system is more sensitive and accurate in detecting thread breakage, which can provide better guarantee for your fine embroidery.

3. Titanium plated gold needles

Each embroidery head of VISION V22-2 is equipped with 15 titanium-plated gold needles, which have higher abrasion resistance and stronger penetration. In the embroidery process, it is not easy to wear or deformation, for the high hardness structure of the hat can also be very good embroidery, and reduce the frequency of needle breakage, which also greatly reduces the consumption of needles. At the same time, titanium-plated needles can also improve the stability of machine embroidery and ensure the precision of embroidery design.

4. Telescopic thread frame

We listened to customer feedback carefully and changed the original non-adjustable thread frame into a retractable thread frame, so that customers of different heights can adjust it according to their own comfort height, so that customers can be more convenient and comfortable during the embroidery process, and the embroidery efficiency can also be doubled.

5. Visualization Shuttle

When you look at the photos of our VISION V22-2 you have noticed that there are two red covers, and this red cover is one of the points of this upgrade. We have added a transparent cover to the VISION V22-2's shuttle. Don't underestimate this transparent cover, it is very useful. First of all, it protects the bobbin from dust and debris on the fabric. Secondly, the transparent cover allows the user to visualize the bobbin, making it easy for the user to safely view the operation of the bobbin during the embroidery process, so that any abnormalities such as tangled threads or broken threads can be detected and stopped in a timely manner.

# Why you need VISION V22-2

After the single head embroidery machine brings you better embroidery quality and higher customer satisfaction, more orders are coming. But a single head machine can't load your orders anymore, if you have a double head machine, you can fulfill your orders quickly, for a 10 hours workload, you only need 5 hours to finish it, you don't need to stay up all night to catch up the production any more, and you can take care of all your orders during the day. That's why you need the VISION V22-2.

· Embroidery machine upgrades allow your store to accept more and larger orders without worry and achieve greater capacity.

For example, if you have a large order of corporate workwear that requires embroidery designs for corporate branding and have a short lead time left for you to complete the order; with a dual head machine you can complete the order within the time frame and handle the pressure with ease. You will get more large orders from customers in the future as you can prove that you can do a lot of high quality work.

· Embroidery items such as hats, towels, blankets, purses, bags and garments in bulk at any time with a double-ended machine. Providing you with the productivity to achieve more.

In addition to the growth in capacity of the double head machine, she also has the ability to produce more targets. Take the V22-2 as an example, it can meet your embroidery on clothes, hats, and leather clothing, you don't have to turn down orders for hats because you are worried that it can only embroider on clothes, the V22-2 can meet the vast majority of your embroidery goals.

· Once you set up a dual-head machine, you'll need fewer interactions, which can maximize your staffing costs and process efficiency.

In terms of productivity, two single-head machines require one more step of operation than one double-head machine. For example, if you are embroidering two garments, a double-head machine only needs to operate one control panel to control two embroidery heads together, whereas two single-head machines need to operate the control panels of both machines separately.

· Accelerated production at cheaper prices, striking a balance between price and productivity.

Double-head machine production efficiency needless to say, must be higher than the single-head machine production efficiency, in terms of price double-head machine is also higher than the single-head machine, the specific price difference depends on the brand of the machine.

After reading the whole article, I believe you have more knowledge about VISION V22-2, and also know that the machine has so many other features, if you still want to know more, you are welcome to leave us a message, we will be the first time to reply to you, you still want to know what can also give us a message, thank you for reading.

-1.png)