Embroidery Machine Needle Skipping Troubleshooting and Solutions

2024-11-01Embroidered Letters: Adding Personalization to Your Stitched Creations

2024-11-22EMBROIDERY TIPS

Chatting about embroidery machine bobbins

POSTED ON NOVEMBER 6th,2024 BY BAi

As a key component of embroidery machines, bobbins play an integral role. In this article, we will delve into the specifications of embroidery machine bobbins, their characteristics and how to select a bobbin, so that you can have a comprehensive look at everything about bobbins.

In this article, the following aspects will be mentioned:

#1 Getting to know bobbins

#2 Classification of bobbins

#3 Selection of bobbin thread

#4 How to adjust bobbin tension

#5 How to maintain and care for bobbins

#6 Suggestions for bobbin purchasing

#1 Getting to know bobbins

The bobbin is a component installed in the shuttle case to provide bobbin thread for embroidery. As we all know, embroidery threads are divided into two types: top thread and bobbin thread. During the embroidery process, the top thread and bobbin thread intertwine to create stitches. The thread wound on the shuttle core is the bobbin thread.

#2 Classification of bobbins

There are various types of bobbins for embroidery beginners, it is important to have a good understanding of the characteristics of different bobbins and select the appropriate one based on their specific needs. Generally, bobbins can be classified from the following perspectives.

-1 Winding method

From the perspective of winding method, shuttle cores can be divided into pre-wound bobbins and empty bobbins.

Pre-wound bobbins

As the name suggests, pre-wound bobbins come already wounded with threads, eliminating the need for users to manually wind the thread or use a bobbin winder. These bobbins can be directly used on the embroidery machine, saving users the hassle of winding and significantly improving work efficiency.

However, these bobbins are disposable and cannot be reused. At the same time, using disposable bobbins may cause some problems. Many users in the use of embroidery machines, often faced with the problem of unstable thread cutting, where sometimes the thread can be cut and sometimes it cannot. One of the reasons for this phenomenon is the use of disposable bobbins.

Common pre-wound bobbin available in the market is basically from China, whether purchased on Amazon or elsewhere, it is of low quality and the thread on this bobbin is basically polyester thread, no cotton thread. Therefore, it is not recommended to use pre-wound bobbin when embroidering high-quality embroidery products.

Empty bobbins:

When users purchase empty bobbins, there is no thread on the bobbin, and the user needs to manually wind the thread or use a bobbin winder. Users can buy a spool of thread, a bobbin winder, and empty bobbins, and then they can wind the bobbins themselves.

These bobbins can be reused, and if users wind them with a full spool of thread, the cost of the thread will be lower. Therefore, using empty bobbins has a benefit: it can result in lower overall costs. Additionally, users can wind high-quality bobbin thread on empty bobbins, which is meaningful when embroidering high-quality embroidery products.

-2 Material

From the perspective of material, shuttle cores can be categorized into metal bobbins, plastic bobbins, cardboard bobbins, composite material bobbins, etc. Here, the material refers to the material of the "shell" and "core" of the bobbin.

Metal bobbins

Metal bobbins are the most common type, typically made of metal alloys such as steel or aluminum. Metal bobbins have high durability and stability, can withstand high thread tension, and are suitable for various fabrics and embroidery needs.

Plastic bobbins

Plastic bobbins are made of plastic materials. They are relatively lightweight and suitable for lightweight fabrics and embroidery projects. Plastic bobbins usually have lower costs and can be used on some simple embroidery machines.

Cardboard bobbins

Cardboard bobbins are made of cardboard or paper materials and are typically used for temporary or simple embroidery needs. They are suitable for teaching, beginner practice, or some handicraft production.

Composite material bobbins

Composite material bobbins refer to bobbins made of different materials, such as a combination of metal and plastic. These bobbins combine the advantages of various materials, have high stability and durability, and are suitable for some special sewing or embroidery tasks.

In addition, there are some disposable bobbins that have no shell or core at all. They are formed purely by adhesive spraying process without any support structure. Since they have no "shell" and "core," the concept of material does not apply to them.

-3 Shape

From the perspective of shape, bobbins can be categorized into shell shuttle core and shellless shuttle core.

They are distinguished by whether or not the bobbin is protected by a casing on either side, or whether the bobbin is of half-wrapped or full-wrapped structure.

Shell bobbin

Shell bobbins have a protective shell on both sides. They have a fully enclosed structure, providing high strength and good stability. Generally, shell bobbins are made of plastic or metal materials, meaning that both the "core" and "shell" of the bobbin are made of plastic or metal.

No-shell Bobbin

No-shell bobbins do not have a protective shell on both sides. They have a partially enclosed structure, having only the "core" without a "shell". This type of bobbin has lower strength and less stability. Usually, no-shell bobbins are made of plastic or paper materials, meaning that the "core" is made of plastic or paper.

-4 Size

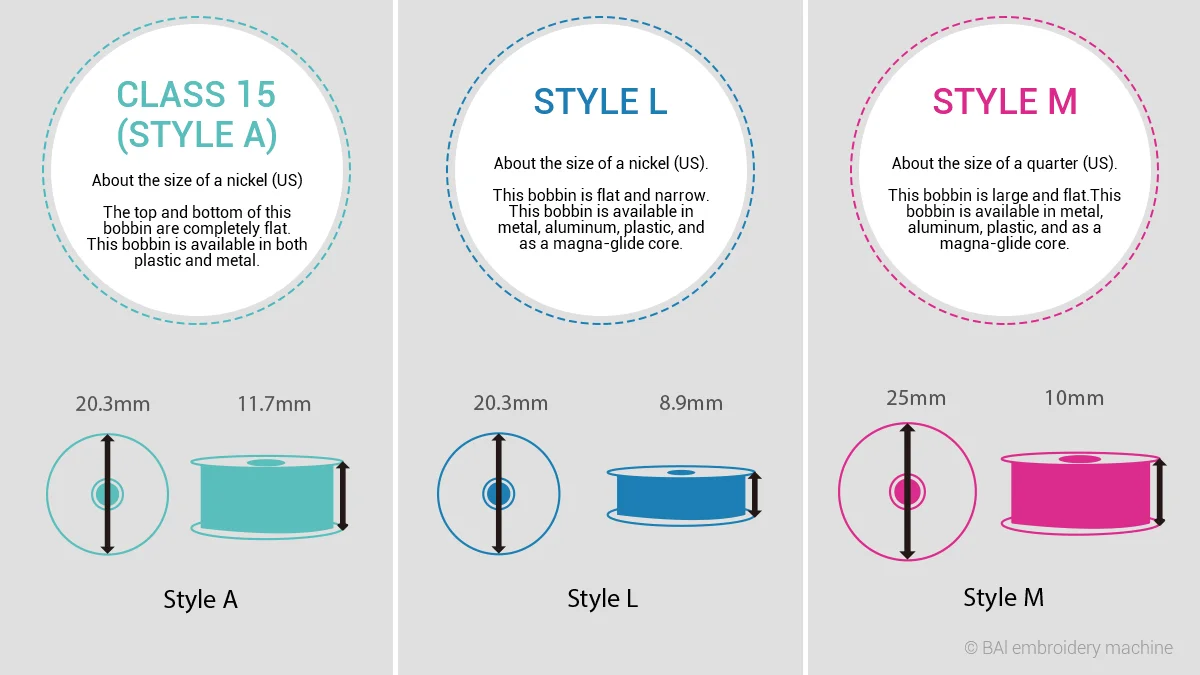

From the perspective of size, bobbins can be divided into three types: L, A, and M. These three sizes are the most common and can be compatible with the majority of embroidery machine brands in the market. In addition, there are other sizes such as J/G/U/Z, but they are less commonly used in the embroidery field.

The differences between these three sizes of bobbins are as follows: The diameter of an L-size bobbin is the same as that of an A-size bobbin, but the A-size bobbin is thicker, allowing it to hold more bobbin thread. The M-size bobbin has a larger diameter.

Not all embroidery machines use the same size of bobbins. Among these three sizes, the L-size bobbin is the most widely used, followed by the A-size and M-size bobbins. When using an embroidery machine, it is important to determine which size of bobbin is compatible with your machine. You can refer to your machine's user manual or consult your sales representative. Not all bobbins that appear to have the right size will necessarily be suitable, so it is essential to confirm the size compatibility.

L-style Bobbin

The L-style bobbin is a common type of metal bobbin, typically cylindrical in shape with raised edges on both ends.

Advantages:

- Wide applicability: L-style bobbins are suitable for various home embroidery machines and industrial embroidery machines, and suppliers are generally easy to find.

- Moderate capacity: L-style bobbins have a moderate thread capacity, suitable for handling small to medium-scale embroidery needs.

Disadvantages:

- Smaller capacity: Compared to some other bobbin models, L-style bobbins may have a smaller thread capacity, requiring more frequent thread changes.

M-style Bobbin

The M-style bobbin is a type of metal bobbin, typically cylindrical in shape with flat ends and no raised edges.

Advantages:

- Large capacity: M-style bobbins usually have a larger thread capacity, suitable for long-duration and large-scale embroidery operations.

- High-speed adaptability: M-style bobbins are suitable for commercial embroidery machines and industrial embroidery machines, capable of accommodating high-speed embroidery requirements.

Disadvantages:

- Relatively less common: Compared to L-style and A-style bobbins, M-style bobbins may be less universally available in certain regions and from some suppliers.

- Metal material: M-style bobbins are typically made of metal, which may produce noise or friction with other metal components during use.

A-style Bobbin (Class 15 Bobbin)

The A-style bobbin is a common type of plastic bobbin, typically cylindrical in shape with flat ends.

They are referred to as A-style or Class 15 bobbins and are available in both metal and plastic materials; however, they do not have the holes on the sides like regular L-style bobbins. Additionally, their diameter is the same as L-style bobbins but wider, allowing them to hold more thread. The regular dimensions of A-style bobbins are typically 3/4 inch in diameter, 3/8 inch in height, with a flat profile. If your machine has a bobbin case that needs to be removed to install the bobbin, you can use both metal and plastic A-style bobbins. However, if your bobbin system has a drop-in feature, you must use the plastic version only.

Advantages: A-style bobbins are typically smaller, suitable for delicate sewing work such as fine needlework and thin threads. Due to their compact size, they can be used in embroidery and sewing of fine textiles.

Disadvantages: Due to their smaller size, A-style bobbins have limited thread capacity and may require more frequent bobbin changes.

#3 Selection of Bobbin Thread

The thread used on bobbins is commonly referred to as bobbin thread. When choosing bobbins, it is important to consider not only the bobbin's support structure but also the selection of bobbin thread.

Bobbin threads also have various classifications. When selecting bobbin thread, embroidery beginners should have a thorough understanding of the characteristics of different bobbin threads and choose accordingly based on their specific needs. Factors to consider include the compatibility of bobbin thread with the top thread, as well as the compatibility with the fabric. Generally, bobbin threads can be classified based on material, weight, and color.

-1 Material

There are multiple materials available for bobbin thread, each with its unique characteristics and suitability. Here are some common materials for bobbin thread:

- Polyester Thread: Polyester thread is one of the most common and widely used materials for bobbin thread. It offers durability, strength, elasticity, and is less prone to breakage. It can be used for various embroidery projects and fabric types.

- Nylon Thread: Nylon thread is another commonly used material for bobbin thread. It provides good strength and durability, making it suitable for handling thinner fabrics and embroidery projects that require higher tensile strength.

- Cotton Thread: Cotton thread is suitable for specific embroidery projects, particularly when working with natural fiber fabrics. It offers a natural texture and softness, and is commonly used for embroidery on cotton fabrics.

-2 Specifications

Common specifications for bobbin thread include the following:

- Thread Density: The Thread density of bobbin thread is typically measured in denier (D), with common specifications such as 40D, 70D, 100D, and so on. Lower thread density indicates finer thread, suitable for intricate embroidery projects, while higher thread density is suitable for thicker embroidery thread or projects that require stronger thread.

- Yarn Count: The yarn count of bobbin thread represents the length of yarn per pound, with common specifications like 40/2, 50/2, 60/2, and so on. Lower yarn count indicates a longer length of yarn per pound, relatively finer, and suitable for delicate embroidery projects, while higher yarn count is suitable for general embroidery needs.

- Thread Size: The size of bobbin thread can also be indicated by thread number, such as 120, 60, and so on. Higher numbers indicate finer thread.When selecting the specifications of bobbin thread, it is important to follow a principle: the diameter of the bobbin thread should be about 2/3 of the top thread. This is a commonly used standard for selecting bobbin thread.

-3 Color

On the market, bobbin thread can be found in various colors, but white and black are the most common. When a embroidery piece is completed, the bobbin thread generally does not show on the surface, so the requirements for bobbin thread color are not very strict. When choosing the color of bobbin thread, many people prefer to select a color that matches or closely matches the color of the embroidery. This minimizes the visibility of the bobbin thread in case it accidentally shows, reducing any negative impact. In practice, considering convenience and cost, most people choose to use white bobbin thread. However, when the fabric is dark-colored, they may switch to black bobbin thread.

#4 How to Adjust Bobbin Thread Tension

Adjusting the tension of the bobbin thread is an important step to ensure smooth supply of the bobbin thread during the embroidery process.

Here are the general steps to adjust the bobbin thread tension:

Locate the Adjustment Device

First, you need to find the adjustment device on the embroidery machine used to adjust the bobbin thread tension. This is typically a screw or knob located near the bobbin area. The specific location and form may vary depending on the embroidery machine model and brand.

Loosen the Tension

Initially, rotate the adjustment device counterclockwise, which is to the left, to decrease the tension of the bobbin thread. This will loosen the bobbin thread spring and reduce the tension of the thread.

Perform Test Embroidery

Carry out a test embroidery and observe the supply of the bobbin thread. If the thread is too loose or not feeding smoothly, you may need to increase the tension of the bobbin thread. If the thread is too tight or experiencing drag, you may need to decrease the tension.

Adjust the Tension

Based on the results of the test embroidery, gradually adjust the tension of the bobbin thread. Rotate the adjustment device clockwise, to the right, to increase the tension. Make incremental adjustments until you achieve the appropriate tension of the bobbin thread. During the adjustment process, you can perform multiple test embroideries to observe the effects of the adjustments.

Perform Final Adjustment

Once you have achieved satisfactory tension of the bobbin thread, conduct a final test embroidery. Ensure that the bobbin thread is supplied smoothly and the embroidery quality is good. If necessary, make slight adjustments to the bobbin thread tension.

Please note that different embroidery machines may have different methods and devices for adjusting the bobbin thread tension. Therefore, it is advisable to consult the user manual of the embroidery machine or contact the embroidery machine manufacturer or technical support team for specific instructions on adjusting the tension for your particular machine.

#5 How to Maintain and Care for Bobbin Thread

-1 Regularly Clean the Bobbin Area of the Embroidery

During the embroidery process, impurities such as embroidery thread, fabric fibers, and dust can accumulate in the bobbin area of the embroidery machine. Regularly cleaning this area is crucial for maintaining the proper functioning of the bobbin thread. You can follow these steps to clean it:

- Turn off the embroidery machine and unplug it from the power source.

- Use a small brush or a vacuum cleaner to gently remove dust and debris from the bobbin area.

- Check for any blockages or tangled thread in the bobbin area, and if necessary, trim them with small scissors.

-2 Replace Worn-out Bobbin Thread Promptly

Bobbin thread can wear out over time, and worn-out bobbins can cause unstable thread tension, poor embroidery results, or even machine malfunctions. Therefore, when you notice signs of wear, deformation, or other damage to the bobbin thread, it is important to promptly replace it with a new one to ensure embroidery quality and the proper functioning of the machine.

-3 Proper Storage of Bobbin Thread

Proper storage can prolong the lifespan of bobbin thread. Here are some suggestions for storing bobbin thread:

- Store the bobbin thread in a dry place away from direct sunlight.

- Avoid exposing the bobbin thread to extreme temperatures to prevent deformation or damage.

- If possible, use a dedicated bobbin case or storage box to protect the bobbin thread and prevent it from rubbing against or colliding with other items.

#6 Bobbin Procurement Recommendations

In terms of embroidery quality, aluminum bobbins are undoubtedly the best among all types of bobbins, despite the need for manual winding. Apart from aluminum bobbins and fully encapsulated plastic bobbins, all other bobbins are produced using adhesive spraying technology, which greatly compromises their strength and stability.

In terms of pricing, among the entire range of bobbins, the 75 D/2-M bobbins are the cheapest because they do not have any bobbin shell or cardboard core. The next in terms of pricing is the 75 D/2-H bobbins, which have a cardboard core, followed by plastic bobbins and then plastic fully encapsulated bobbins. Aluminum bobbins are the most expensive.

Many customers purchase disposable bobbins to save time. They have a high workload and do not have time to repeatedly use aluminum bobbins with a bobbin winding machine. Therefore, they often buy disposable bobbins on platforms like Amazon. If you must buy disposable bobbins, we recommend the type of plastic fully encapsulated bobbins as they offer the best balance between convenience and embroidery quality. However, if you have enough time to wind the bobbins yourself, we still recommend using aluminum bobbins as they will provide the best embroidery results.

Although the bobbin in an embroidery machine may seem like a small component, it plays a crucial role in embroidery. To achieve high-quality embroidery results, it is essential to have a strong understanding of bobbin. Now that you have acquired relevant knowledge about bobbins, it's time to unleash your creativity.

-1.png)