Common Mistakes Made by Beginners in Embroidery

2025-05-09EMBROIDERY TIPS

Exploring Embroidery Machine Speed Issues: A Practical Guide

POSTED ON MAY 30th, 2025 BY BAi

For those who work in the embroidery business, finding the right balance between high-speed production and maintaining top-notch quality has always been a challenge. Speeding up the embroidery process can boost efficiency and shorten delivery times, but if quality drops, it may cost you orders and customer satisfaction. On the other hand, slowing down too much to ensure quality can hurt productivity and make it hard to meet market demands.

So, how can you strike a balance? How can you achieve both high-quality embroidery and fast production to satisfy your customers? In this blog, we'll explore the factors that influence embroidery speed, how speed affects quality, and tips for improving speed without sacrificing quality.

Factors Affecting Embroidery Speed

1. Machine Performance

- Machine Model & Technology: High-end embroidery machines are equipped with precision motors, advanced control systems, and durable parts, which can significantly boost speed. Lower-end models may lack the power and accuracy to keep up.

- Machine Condition: Regular maintenance—like cleaning, lubricating, and checking key parts like the needle plate, bobbin, and frame—is essential. Machines that aren't well-maintained can slow down due to worn-out components.

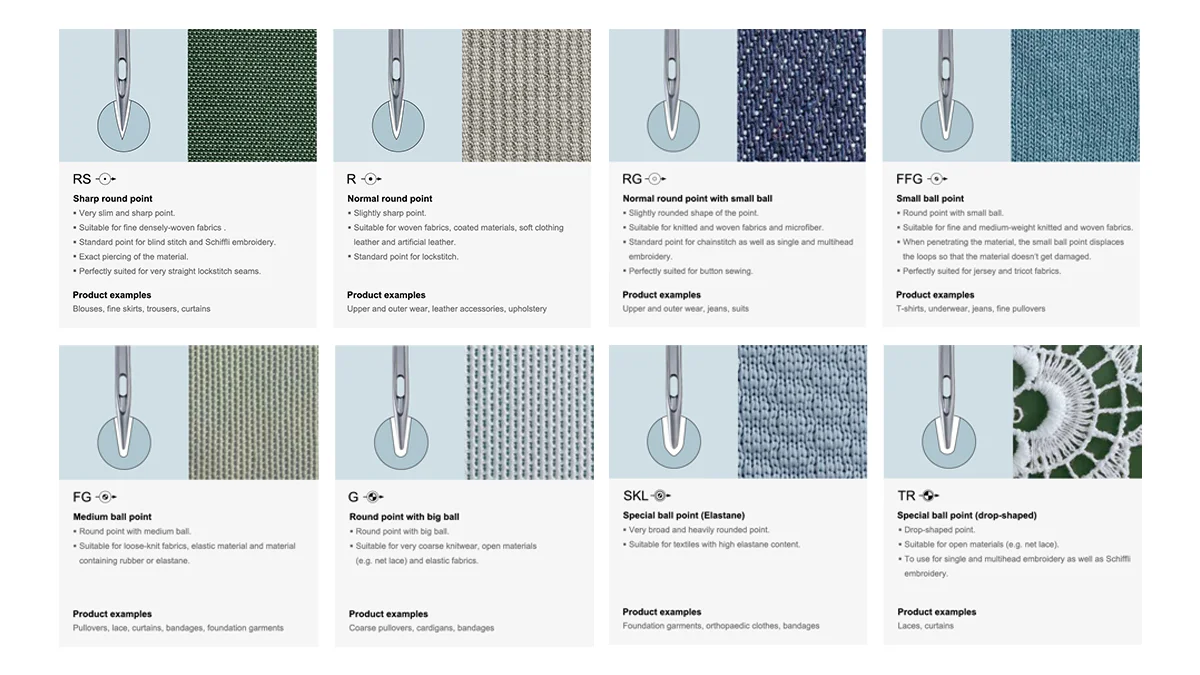

2. Needle Quality & Type

- Needle Types: Different needles, such as sharp, ballpoint, or fleece needles, suit various fabrics. Choosing the right one reduces friction and boosts speed. For example, fine needles work best on lightweight fabrics, improving stitch flow.

- Needle Condition: Bent or worn needles increase friction and can cause thread breaks. Regular inspections and replacements keep the machine running smoothly and efficiently.

3. Fabric Typey

- Thickness & Texture: Heavier fabrics like denim require slower speeds to maintain clean stitches, while lightweight fabrics like silk need careful tension adjustments at higher speeds to avoid distortion.

- Elasticity: Stretchy fabrics, such as Lycra, may warp at high speeds. Using elastic needles and adjusting the machine’s tension can help maintain fabric stability even at faster speeds.

4. Thread Quality & Type

- Strength & Flexibility: High-quality threads like polyester or silk are durable enough for high-speed tension. On the other hand, low-quality threads tend to break or fray more easily.

- Thread Type: Metallic threads, such as gold or silver, wear out more quickly at high speeds, so it's best to adjust speed for these types to avoid thread damage.

5. Design Complexity

- Detail Level: Complex designs with tiny details require slower speeds for accuracy. However, using embroidery software to optimize design paths can help you achieve faster stitching without sacrificing detail.

- Design Size: Larger designs can handle higher speeds, but stabilizing the fabric and maintaining stitch uniformity is key to preserving quality.

- Stitch Type & Density: Densely packed stitches or intricate techniques like satin stitching take longer to complete, impacting speed.

6. Operational Settings

- Tension Settings: Proper thread tension is crucial to avoid thread breaks or tangling during high-speed embroidery. Adjusting the tension based on the design and material ensures smoother, faster stitching.

Impact of Embroidery Speed on Quality

Finding the right speed for your machine is all about balance. Too fast, and you risk uneven stitches, thread breaks, and fabric distortion. Too slow, and productivity suffers, driving up costs. Here’s how speed can influence quality:

1. Quality Stability:

High-speed stitching increases friction between the thread, needle, and fabric, leading to potential issues like thread breaks or fabric pulls. Slowing down reduces these risks, ensuring smoother, more consistent results.

2. Detail Precision:

When stitching complex designs, higher speeds can cause misalignment in needle placement, resulting in blurred details. Slower speeds allow for greater control, which is critical for logos or badges with fine details.

3. Fabric Protection:

High-speed embroidery puts extra strain on delicate fabrics like silk, leading to potential damage. Slower speeds distribute tension more evenly, helping to protect fragile materials from distortion or wear.

Methods to Increase Commercial Embroidery Machine Speedn

1. Use High-Performance Machines:

- Opt for machines with advanced features like auto-thread trimming, color changes, and tension control to save time.

- Regular maintenance ensures the machine operates at its peak speed without interruptions from worn-out parts.

2. Select the Right Needles & Threads:

- Invest in quality needles and threads from trusted brands like Schmetz or Organ to reduce friction and minimize thread breaks at high speeds.

- Regularly replace needles, especially after high-density stitching projects, to keep the machine running smoothly.

3. Optimize Designs:

- Use embroidery software (e.g., Wilcom) to streamline designs by reducing unnecessary details and optimizing stitch paths, which helps cut down on stitching time.

4. Manage Fabric Tension:

- Adjust thread tension according to the fabric you’re using, and use tension tools to ensure even stitching at high speeds.

5. Train Operators:

- Regular training ensures that machine operators can troubleshoot and optimize machine settings to maintain both speed and quality.

In conclusion, embroidery speed depends on a variety of factors, and by fine-tuning each parts, you can significantly improve your overall efficiency. With the right balance, you can achieve fast, high-quality embroidery that satisfies both market demands and customer expectations.

-1.png)